Since the mid of the 19th century, the main source of cellulose fibres has been wood. The fibres are separated either chemically or mechanically from naturally occurring species. In the case of Holmen, it is mainly spruce, pine and birch from sustainably managed forests in Scandinavia and other European countries.

These forests are maintained and expanded by industries that depend on good access to wood. As a result of these efforts, the growing tree population is increasing each year. In many areas, growth now exceeds the amount of timber harvested.

This careful forest management ensures that forests continue to be part of nature's sustainable cycle and provide a lasting source of raw materials.

Cellulose and the Laws of Nature

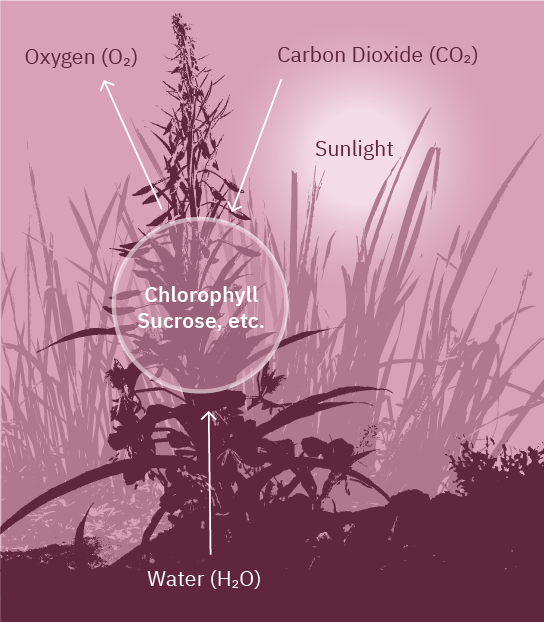

Carbon dioxide and water are converted into simple glucose-based sugars by the action of sunlight on the green, chlorophyll-containing cells of the plant kingdom. This process is called photosynthesis and involves the release of oxygen. Natural sugars can be polymerised in plants to produce cellulose.

The photosynthesis process.

Cellulose has a high molecular weight and a straight-chain molecular structure. Plants use cellulose to grow by building cells – fibres – and other structures supporting the plant's life. Each species has its characteristic fibrous structure. Many species of trees have been cultivated and developed over time into renewable sources of raw material for producing a wide range of paper and paperboard products. Therefore, careful forest management and manufacturing paper products are closely linked.

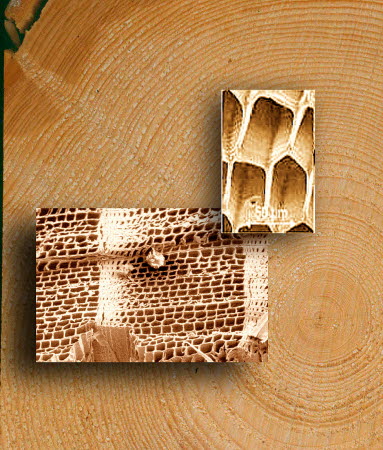

Different levels of magnification of the wood fibre reveal the difference between the seasonal growth, and a close-up of the fibre shows its hollow interior and the thin layer of lignin holding the fibres together.

Cellulose makes up about 44 % of wood fibres. Pure cellulose fibres are soft, flexible, and white. The other components are hemicelluloses, lignin, and extractives.

Hemicelluloses are a group of substances related to cellulose but with a lower molecular weight and a more complicated chain structure. Lignin is a more complex polymer and is very different from cellulose, being hard and brittle. Both hemicelluloses and lignin are present in the fibre, but the main concentration of lignin is between the fibres, giving adhesion and stiffness to the wood structure.

The fibre separation process, or pulping, takes advantage of the differences between lignin and cellulose.

Fibre properties based on tree diversity

The fibres in a tree trunk run parallel to its length. The fibre length varies depending on the tree species. The ratio is shown in the following table.

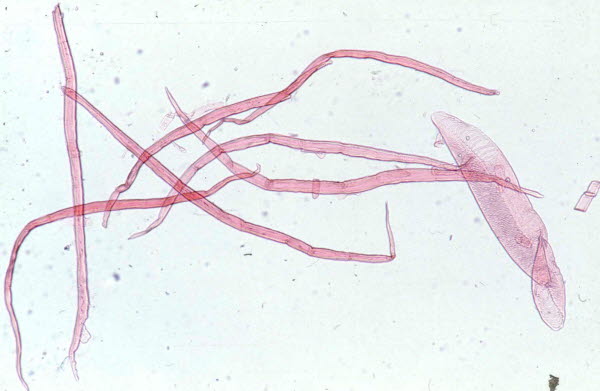

Birch fibre - short and cylindrical.

Spruce fibre - long and flat.

Pine fibre - long and flat.

Mixed fibres of spruce, pine and birch.

| Species | Fiberlength mm | Fiber width mm | Shape |

| Spruce | 3.1 - 3.5 | 19 - 50 | Ribbon flat |

| Pine | 2.0 - 3.0 | 22 - 50 | Ribbon flat |

| Birch | 0.9 - 1.2 | 20 - 35 | Cylindrical with pointed ends |

Other natural laws

There are natural properties that all wood fibres exhibit to a greater or lesser extent, as well as specific properties associated with the fibres of particular tree species. The pulping process also influences fibre properties.

Fibres general properties

- The ability of the fibres to grip each other and join together to form a strong, homogeneous structure.

- The flexibility, shape, and dimensional properties allow the fibres to create a uniform interlaced network.

- The ability of fibres to be positively modified during the production process, either mechanically or through the use of additives.