Contact the Iggesund mill for more information:

Welcome to Iggesund mill

View in SwedishInformation for contractors and suppliers

On this website we have collected the most important safety information for the the mill in Iggesund. The aim is to provide an initial brief set of information about general safety rules as well as what to do in the event of an accident or gas emission. Also download the "SSG On Site" app to keep yourself updated and informed.

We want those who work for us or visit us to feel safe and secure at our mill in Iggesund. One condition for us to succeed is for you to comply with applicable safety regulations and use the prescribed protective equipment.

Hardly any workplace can be made completely safe, but by planning the work, as well as by inventorying and preventing risks, those of you who work here can contribute to a safer workplace and a better work environment for yourselves, your colleagues and visitors to the mill in Iggesund.

Download the SSG On Site app

Download this information as a PDF

Find Iggesund mill

GPS coordinates:

Security information

Coordination

At the mill in Iggesund, the Maintenance Manager is appointed as the coordination officer for protective measures in shared workplaces, where contractors/ suppliers are involved. An organisation has been set up to continually supervise the collaboration between the different companies that carry out work at the mill. Notice of the appointed coordination officer and the organisation for collaboration is pinned on the notice board next to the gatehouse.

Contractors/suppliers are obliged to acquaint themselves with the regulations that apply in the workplace concerning conduct, fire protection, worker protection etc. before the work commences.

Contractors/suppliers must inform their staff about the applicable regulations and monitor to ensure that they are followed.

Contractors/suppliers must inform the purchaser's coordination officer/contact person to identify the supervisor(s) and inform these of the responsibility they have for safety and protection issues. In the case of uncertainties of any type, contractors/ suppliers must always contact the coordination officer/contact person.

ENTRÉ – security education for contractors

Before you as a contractor are permitted to work independently within the factory area, you must have completed the web-based security course ENTRÉ provided by SSG, as well as go through Iggesund's local safety course, which can also be found on the SSG website. You can find the SSG Entré basic course here.

Personal protective equipment

All workers are obliged to use protective equipment and the prescribed safety equipment. There is some equipment available for loan from the Protection Depot in Iggesund.

Contractors/suppliers are responsible for providing their employees with the personal protective equipment that their operations may require.

lf contractors/suppliers do not have access to gas protection material, in exceptional cases, this can be purchased from Iggesund Mill's central store.

Safety helmets must be used by all staff - even production staff - when maintenance and assembly work is being carried out.

Safety shoes are obligatory in all production areas. An exception is made for our guests during guided tours.

Warning vests or equivalent warning grade 2 on the upper body must be used by everyone in outdoors areas inside the gates.

Hearing protection must be used when the noise level is high; this is marked on the door.

Eye protection must be used at all times where there is a risk from corrosive liquids or splinters.

Respiratory protection must be carried and used in certain work areas. Where gases occur, consult your coordination/contact person.

Fall protection must be carried and used while carrying out certain types of work. Consult your coordination/ contact person.

Gas meters must be included in all cellulose production premises that are equipped with a gas warning alarm.

Procedures and regulations

When arriving at the mill, all visitors and contractors must report their arrival at reception! Entrance to the industrial area must be done through the main gate, if you do not have an entrance card.

Contractors/suppliers must obtain information about the specific regulations that apply for access and exit as well as for goods transportations. Random inspections can occur. Entry permits for minors (10-15 years of age) are granted by the Site Manager, Production Managers, HR Manager, Maintenance Manager, Communications Manager or Production Supervisor for Cellulose.

Traffic regulations

- The statutory traffic provisions on traffic regulations apply in applicable areas within the industrial area.

- Speed is limited to 30 km/h.

- Passes for cars are only granted on special occasions. Ask your coordination/ contact person.

- Parking is only permitted in the places indicated.

- The TM4-yard, the EBH-yard and the courtyard is prohibited for unauthorized traffic.

Photography is forbidden within the entire mill area. Permission can be granted by the Site Manager, Maintenance Manager, Production Managers and the Communications Manager. Ask your coordination/ contact person or the gatekeeper.

Order, waste collection and cleaning are an important part of protection. Everyone is obliged to clean up after themselves in their workplace, routines for the sorting of waste apply. There are special storage points for welding carts and gas cylinders. Ask your coordination/contact person.

Smoking and drugs

Smoking is forbidden within the entire mill area, except for those places where it is clearly stated that it is permitted. Individuals who are under the influence of alcohol or other drugs are not permitted in the mill area. Drugs are prohibited within the mill area. Checks may occur.

Reporting burglary/theft

All burglaries and thefts must be reported as soon as possible to the Maintenance Manager 073-029 93 25.

Hot Work is all types of work that can cause a fire. At Iggesund Mill, you must have a personal certificate and insurance for "Hot work" and you must comply with our local regulations.

Electrical isolation

Before any work can commence you must assure yourself that the work object is safely shut down according to the "Basic rules for electrical isolation".

The routine "Safe stops" must be followed.

Work below the floor

Under most of the factory floors there are spaces where, among other things, cable trays, aerial cables and groundwater pumps are located. During work in these confined places, there is always a certain risk of being unconsciously influenced by gases such as hydrogen sulphide, carbon dioxide and, perhaps, in certain restricted spaces, carbon monoxide. Contractors/ suppliers are obliged to contact Iggesund Mill's coordination/ contact person before commencing work. Procedure: Work permit for work in containers or restricted spaces.

Safe lifts

Iggesund Mill has local rules for lifts with mobile cranes, HGVs and such like. Consult your coordination/ contact person. Lifts with straps and other lifting tools must be carried out in a safe manner. Assure yourself that the lifting tools are safety tested and approved before you use them.

Certificates and operating permits are required for the use of lifting equipment, lifting tools and for the use of forklifts.

Chemicals

Poisons and substances injurious to health as well as explosives must not be taken into the industrial areas/work sites or stored there without the approval of the coordination/ contact person. In the event of a chemical emission to soil, water or air, it must be reported immediately to the gatekeeper on the alarm number +46 (0)650-288 88.

Material transported off-site

For material that belongs to Iggesund Mill, the coordination/ contact person issues exit instructions.

For material that is to be disposed of on an industrial tip, permission must be obtained from the coordination/ contact person.

Water purification

During work in the wastewater purification plant, respiratory protection with P3 filter must be used. Legionella can occur, therefore pregnant women and individuals with reduced immune defence are not permitted in the area.

GSM telephones

In some, marked areas within Iggesund mill, the use of mobile telephones using the GSM system is not permitted because of the risk of interference with our data and control systems as well as other electronic equipment.

Scaffolding must be inspected and approved before entering it is permitted. It is not permitted to make changes to scaffolding that has been erected.

Barriers must be respected. Deficiencies in barriers must be reported immediately to the responsible person for the department or the contact person.

Evacuation routes in the event of fire, gas emissions or other dangers are marked with the evacuation symbol. Inform yourself about assembly points that applies to you.

Zone classified areas where explosive atmospheres can arise. Visitors are not permitted in these areas without permission.

Radiation sources are installed for measurements. Respect individual signs and shutdown instructions.

The port area

When vessels are in port for unloading or loading, a strict ban on unauthorized people visiting the area prevails. The dockers monitor the area and evict individuals without a permit.

External environments

Statutes, ordinances and decisions of government agencies regulate those parts of the operations that affect the external environment. This can concern emissions to water and air as well as the handling of waste and hazardous waste. In addition to this, there are routines at Iggesund Mill, for example for sorting waste. In the case of doubt, ask your coordinator/ contact person about what applies.

Safe stops

The purpose of safe stops is to provide safe routines for operations in the work equipment's risk area in order to prevent personal injury.

Application

The routine must be applied in the case of all temporary jobs that are carried out in the work equipment's risk area. This includes all precautions; human, technical as well as organisational, that are taken to prevent unwanted (unintended) start of, or processes in, work equipment. The routine covers all forms of energy, such as electricity, hydraulic, pneumatic, mechanical energy, steam, gases and radiation. All staff categories are covered, e.g. production, maintenance and contractors.

Risk assessments are made when establishing a checklist for safe stops. Before using work equipment, the job must be risk-assessed and the necessary safety measures taken.

Separate operation

There is an exception to the requirement for a work permit for so-called separate operation. In the case of separate operation, contact must always be established with the operator for the process section concerned. The process operator decides whether the production will be isolated and locked, and whether they must carry out a test start, or whether this can be done by the executor. The executor must then use a separate lock.

Separate operation is where the operation is performed by individuals who can shut down the work equipment in a safe manner, where the executors have control of safety at the operation site, and where it cannot affect the risk for other equipment.

Separate operation is when the executor has control of safety at the operation site and where it cannot affect the risk for other equipment.

Alarm information

1. Major gas alarm

Routine for triggering a "Major Gas Alarm":

- Alarm the gatekeeper, tel 0650-288 88, when you detect gas.

- The gatekeeper contacts the Production Supervisor Cellulose, tel 0650-283 59, who makes an assessment of the extent and the type of gas that is leaking out.

- The gatekeeper triggers the alarm.

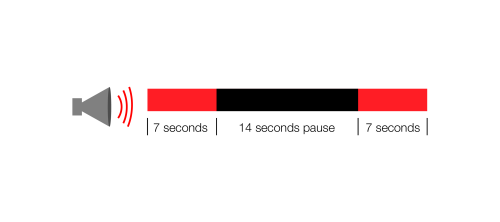

Signal for gas alarm via siren (important message): Short blasts of sound for two minutes.

"Danger over" is signalled by a 30 second long unbroken signal.

Siren tests are carried out every Monday (except public holidays) in March, June, September and December at 3:00 pm. The test alarm is followed by the signal "Danger over".

2.Minor gas alarm

This gas alarm should be started in the event of a minor gas leak within a department. This type of alarm is to be found on line 3, line 4, chemical preparation, the soda house, the vaporisers, the mixer and pump station 2.

The alarm consists of:

Indoors: Red flashing lights combined with rapidly pulsating sound.

Outdoors: Yellow flashing light. These alarms are tested every Sunday at 10 am.

3. Explosion alarm

This alarm is an alarm signal that sweeps up and down in frequency over 3 seconds. In the event of an alarm, the building must be evacuated immediately.

4.Fire

Alarm the gatekeeper, tel. 0650-288 88, and ask for the emergency services.

5. Alarm next to lift shafts and travelling cranes

The danger alarm by lift shafts and travelling cranes consists of yellow warning lights.

6. Process signals

In most of the departments, apart from the alarms described above, there are a number of alarms and signals with various meanings. This can be a signal for the start of machinery, process error, fire alarm etc.

7. Explosion alarm gas station

Automatic start of the alarm on a leak.

IN THE EVENT OF AN ACCIDENT, IT IS IMPORTANT THAT YOU ACT IN THE RIGHT WAY!

-

Save: Those who are in immediate danger.

-

Warn: Others who are in or close to the risk area.

-

Alarm: Phone number: 0650-288 88.

Rule violations

What happens if Iggesund's instructions are violated?

If a contractor repeatedly or grossly disregards these instructions, or other regulations from Iggesund, Iggesund Mill can demand that those concerned be no longer entrusted to work on behalf of the mill.

In case of emergency

Answer the gatekeeper’s questions

• What has happened?

• Where is help needed?

• Is anyone injured? How many? What type of injuries?

• Is the injured person conscious, is he/she breathing, is he/she trapped?

If someone calls 112 by mistake, which is answered by SOS Alarm, the gatekeeper must be informed at once.

Before help arrives

• Can you help those injured without taking any risks?

• Warn others!

If the emergency number does not work:

Call +46 (0)70-370 82 70

The telephone is answered by the gatekeeper and is used to call for ambulance, emergency services (fire brigade), police or first-aid.

In case of emergency, call +46 (0)650-288 88

Fire

Call 0650-288 88 (the gatekeeper) and ask for the emergency services (fire brigade).

In the event of fire, you must save, alarm and extinguish. When you raise the alarm, you must state where the fire is and then arrange for a guide to meet the emergency services at the gatehouse.

First aid in the case of minor accidents

Call 0650-288 88 (the gatekeeper) and ask for first aid.

Accidents

Call 0650-288 88 (the gatekeeper) and ask for an ambulance. Arrange for a guide to meet the ambulance at the gatehouse. If an accident occurs outdoors, you must state the ambulance station from which the transport is to take place. First-aid personnel are always called out in the event of a casualty.

Threats or gas

Call 0650-288 88 and explain what has happened.

If the alarm goes off

If gas emissions occur

At Iggesund Mill, various chemicals are used for the manufacture of paperboard. Based on risk analysis, Iggesund mill works together with Norrhälsinge Emergency Rescue service with extensive safety precautions regarding chemicals to prevent

accidents.

Despite all of our rigorous precautions, accidents may still occur. Gas emissions can affect people working in the factory area and even those living in the surrounding areas around the mill. The gas spreads with the winds' direction, therefore it is important that you who live and work in Iggesund share this information with people around you.

What should I do?

- In case of emergency, call: +46 (0)650-288 88!

- Go indoors!

- Close all windows, doors and ventilations!

- Listen to Radio Gävleborg (P4), frequency 100.7 MHz!

- Stay indoors and wait for further instructions!

- If immediate first aid is needed - contact a doctor!

How do I know when the danger is over?

When danger is over, a long alarm signal sounds for 30 - 40 seconds. Siren tests are carried out every Monday (except public holidays) in March, June, September and December at 3:00 pm. The test alarm is followed by the signal "Danger over".

More information

General documents with important safety information for download.

In case of emergency!

In case of emergency! (Swedish PDF)

Site information and maps

Assembly point in case of fire

General information

Links to SSG on site, as well as other useful information about Iggesund.

SSG On Site education

SSG Entré Holmen Iggesunds Bruk (local safety course)

Accomodations

Quality Hotel Statt Hudiksvall

About Hudiksvall county

Hudiksvall municipality office