The term "paperboard" is defined in different ways.

According to the ISO standardisation body, a paper product with a grammage exceeding 200 g/m² is called a paperboard. However, the Confederation of European Paper Industries (CEPI) definition reads, "Paper is usually called board when it is heavier than 220 g/m²".

Paperboard can be made in a single ply or, more commonly, in multiple plies (multi-ply). For quality reasons, a combination of various wet fibre layers is usually required for the production of paperboard. When studying the traditional paperboard market, it can be seen that multi-ply paperboard is produced as low as 160 g/m².

Two specific features distinguish paperboard compared to paper:

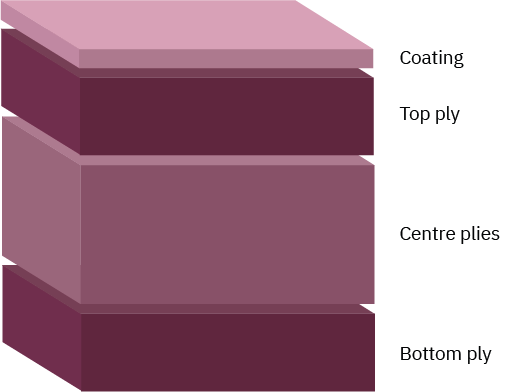

Cross section of a multi-ply paperboard.

- Paperboard contains a higher proportion of long fibres than paper.

- Paperboard does not usually contain fillers.

At Holmen, we claim that paperboard is a heavier paper product with a multi-ply structure.

The advantages of the multi-ply structure are that it is possible to optimise the fibre properties in the different plies to achieve specific functionalities. This is done by varying the content in each ply. The main characteristics to be varied are:

- Proportion of long and short fibres in the respective plies.

- Type of the pulping process.

- Treatment of the pulp to improve strength or bulk quality and distribution of broke in the structure.

To fully exploit the potential for optimising the properties of the paperboard, the multi-ply structure must consist of at least three plies.

The presence of a middle ply allows the paperboard maker to optimise the surface properties of the outer plies without losing the stiffness and paperboard converting advantages built into the middle ply. The dual-ply or single-ply construction will always result in one or more compromises. The following properties are easier to optimise in a multi-ply construction than in a single-ply construction without compromising:

- Bulk

- Strength

- Stiffness both through high thickness and strong outer plies.

- Surface smoothness in combination with desired strength or stiffness performance.

- Functional characteristics in the respective plies, such as increased moisture resistance in the surface or middle plies.

The ability to modify all of these parameters has led to a wide range of industry products targeting specific applications, and end uses through tailored properties, as seen in the following pages.

The advantage of a multi-ply design in a paperboard mill is that the quality can be adapted to different end uses by fine-tuning the abovementioned characteristics. This allows a single supplier to manufacture and supply paperboard for the requirements of various end uses, whereas a single-ply or dual-ply manufacturer has limited options.

Characteristics of the production

At the beginning of the 20th century, the production and distribution of goods and food products increased, and with it, the demand for better protection of these products increased. A cheap and simple solution was using boxes made of thicker paper.

The change in retail from selling loose products to selling pre-packaged products placed new demands on the packaging, which had to serve the purpose of protection and presentation. Getting consumers to recognise a product in the store and pick up a particular product for purchase became increasingly important.

Paper manufacturers had to specialise in meeting the demands of box converters for strong and rigid boxes that would protect products from collapsing during transportation and provide good printing and display capabilities.

There needed to be more than the traditional thick paper. As a result, the first paperboard machines were developed in the United States.

Board machines are typically built for optimal production between 200 g/m² and 1000 g/m², while paper machines have their optimal production basis weight between 70 and 200 g/m², depending on the intended application/end use.

From a layman's perspective, paperboard and paper machines can look very similar. The differences lie in the details. To examine these, we have to take a look at the different sections of the two machine configurations.