Embossing

Embossing and debossing are strikingly impressive design techniques. Embossing creates a raised image and debossing creates an indented image. Either way you add far more than just a touch of class to your products – you give them an almost matchless look of quality.

The best is good enough

When only the best is good enough for a brochure, book cover, folder, card or menu, it may be just the time to use embossing or debossing. You can use the relief as a most eyecatching decoration or in a very understated way to emphasise the name of a company on an exclusive annual report. Although the operation is a challenging one, the possible patterns are almost limitless when you use paperboard.

Fine details or complicated patterns

To emboss or deboss is to shape the paperboard into well defined permanent relief patterns. The method might be applied to create a pattern covering the entire surface or as a pronounced relief. By using both embossing and debossing in the same pattern, an effect of great depth can be obtained.

When using multi-ply paperboard you are able to create very fine details or small details close together without being afraid of having a indistinct result or breaks in the board surface.

Not all paperboards can handle deep relief patterns.

Embossing may sometimes also be of very practical value.

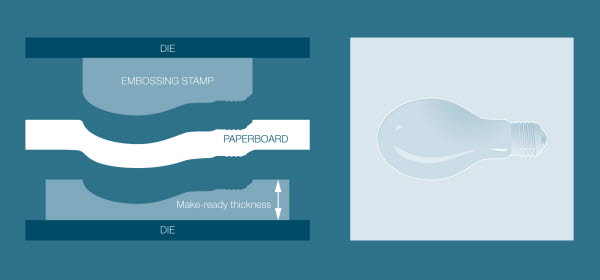

The embossing and debossing operation

This operation is carried out with heat and high pressure to make the relief pattern precise and permanent. The tool consists of a stamp and a make-ready (or counter-die). The make-ready is a thin metal sheet with a groove shaped as the relief pattern, while the stamp carries the inverted pattern.

To create the relief, the stamp pushes the paperboard into the groove of the make-ready.

A severe test of the paperboard

Even though all types of paperboard can be embossed and debossed, there are restrictions due to their construction and composition. The operation is a severe test of the strength, resilience, and surface finish of the paperboard. The inner layers must be flexible enough to be reshaped but not crack. Of course the surface must not crack either, so it must be both strong and smooth. Another important aspect is the necessity not to flatten the relief patterns when the sheets are packed tightly into stacks. To prevent this, the paperboard has to be strong, resilient, rigid and flexible.

Foil embossing and other combinations

Let the relief make its own impression – or combine it with other creative techniques. There are many different ways to achieve an immediate and striking impact. Foil embossing is a way to combine relief and foil in the same operation. A combination die is used: that is, an embossing die with a foil breakage edge to the image area. You may of course also choose print, varnish, or hot foil stamping in separate operations to add whatever effects you can imagine to the relief.

Hot foil stamped, printed with four colours, varnished and finally embossed.