Today's brands want to be sustainable and premium. By offering knowledge, expertise and support in developing new packaging concepts, we enable them to be both. Learn more in our press release.

A climate-smart insert tray

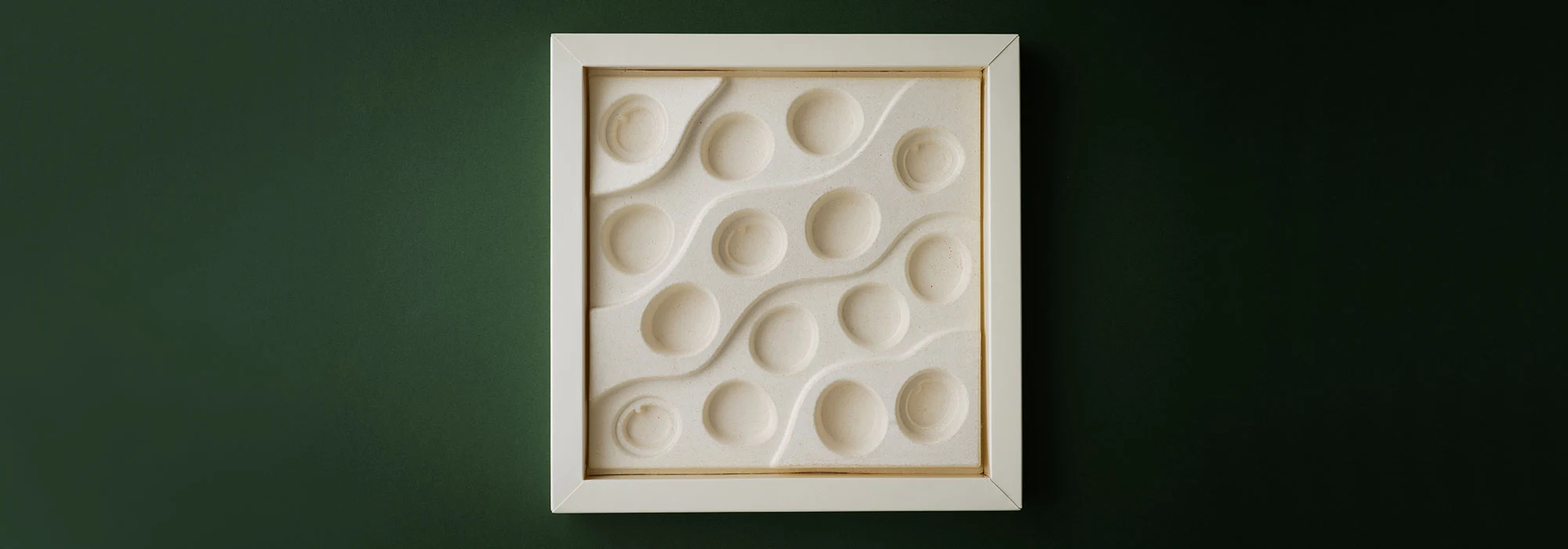

The Choco box shows how to lower a packaging’s CO2 footprint without compromising on design or food safety.

About Choco

Made entirely from renewable materials, the Choco box consists of an outer box and an insert tray with various cavities at different levels for individual chocolate pieces.

The insert tray is made from Holmen's Mouldable, a food-safe material consisting of long and short fresh fibres, which has a much lower CO2 footprint than it’s plastic forebearer. Replacing plastic trays with the new mouldable material would lower the CO2 footprint by 90% in terms of raw material.

“Today, most chocolate-boxes contain plastic trays,” says Hein Van den Reek, Director Future Packaging, Holmen. “But this prototype shows that we can completely substitute the plastic with renewable materials and still have something that is a beautiful design using different shaping techniques. And of course, this can be done for cosmetics, electronics and many other applications.”

The partners

Holmen

Holmen has provided the renewable wood-based raw materials that the Choco box project is made from.

The outer box is made of Invercote Creato 400 g/m2, while the insert tray is made from Holmen's new Mouldable material.

Goerner Formpack

Goerner Formpack are pioneers in pulp packaging and visionaries for a world without plastic.

“We all need packaging, but we have to think about what kind of packaging we use, where it comes from and where the end-of-life cycle is, which we believe should be ongoing,” says Managing Director Elisabeth Goerner. “Our main driver for the project was to develop a pulp tray for direct food contact that would remove single use plastic from customers’ packaging departments.”

HP Molded Fiber Advanced Tooling Solutions

HP is focused on delivering technology that accelerates the transition from single use plastic to sustainable solutions like moulded fibre.

“With the packaging material transition in front of us we need all partners in the value chain to create and support developments to enhance the capabilities and performance of the moulded fibre industry,” says Dick Huizinga, Business Development and Sales Lead EMEA, HP Molded Fiber Advanced Tooling Solutions.

FutureLab & Partners

FutureLab & Partners are accelerators of new technologies and circular systems. Their business model is based on close collaboration with partners in the materials, products and packaging value chain. FutureLab & Partners are the concept and system design partners of the Choco box project.

Contact us

Talk to us about how to create new and pioneering solutions that replace rigid plastic packaging! Submit your message and contact details using the form below, and we’ll shortly get in touch.

The future of packaging

At Holmen, we aim to form the future of packaging together with our customers and find new ways to develop the packaging solutions consumers will demand tomorrow. Scroll sideways to discover our latest collaborations.